Why use a turbo blanket?

The purpose of a turbo is to compress air and in turn force more oxygen into the cylinders of your engine, this extra air allows the engine to use additional fuel and make a larger explosion (more power!). The basic principle of any turbo is that hot exhaust gasses rushing out of the engine enter a turbine which spin a compressor and force ambient air into the engine.

Having hot exhaust gasses run through the turbo leads to extremely high temperatures within the turbine, this makes the turbo the hottest component under the bonnet. In this article we look at the benefits of fitting a turbo blanket and why you would possibly choose to take something so hot and insulate it further.

What do turbo blankets do?

Turbo blankets are designed to fit around the turbine and insulate the turbo. When installed they keep the heat in the turbine and prevent this higher temperature from soaking into the surrounding area under the bonnet. For aftermarket exhausts there are a number of major advantages to be had from installing a turbo blanket.

Turbo blanket benefits

We get asked “are turbo blankets worth it?”. For most stock turbos on road cars we would generally suggest that turbo blankets are not required, car manufacturers will build the engine with the knowledge it will have a turbo and what size this will be, they will allow sufficient room for this and fit turbo heat shields where necessary. Where aftermarket turbos are fitted, such as tuned road cars and performance race cars, we would always recommend to fit a turbo blanket and unlock the available benefits.

Reduce intake temperatures:

Engines enjoy cooler ambient air temperatures, when air is cooler it is more dense and contains more oxygen per unit volume, this additional oxygen can be utilised to burn more fuel and increase power. The bonus of running a Turbo is that it is forcing more of this air into the cylinders of your engine, the downside is that Turbos get very hot and raise the ambient temperature under the bonnet which means the available air is less dense. The ideal situation is to keep the heat inside the Turbine of your turbo so that the available air for the intake is cooler and more dense, this is where a quality turbo blanket comes into its own. Having the turbine insulated essentially keeps the hot side of your turbo hot and the cool side of the turbo cool which is the perfect balance for a turbo to run efficiently.

Turbo runs more efficiently:

We have spoken about the benefits of having cool air available for intake but it is worth mentioning that keeping heat within the turbine actually brings its own benefits. Hot gasses are more expansive, this is great news for a turbo because the hot exhaust gasses entering the turbine have lots of energy which creates the pressure needed to spin the turbine. Fitting a turbo blanket will hold the heat within the turbine which aids this process, leading to faster spool up of the turbo. While this doesn’t necessarily lead to top end power increases, it does mean that you have access to the available power sooner and more responsively with a more linear power curve.

Protect components from heat soak:

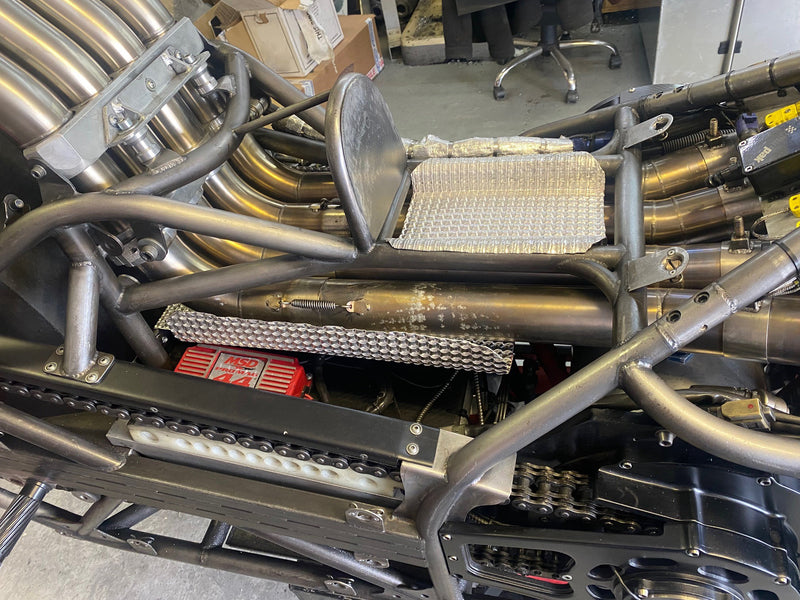

By now we probably don’t need to mention that turbos are hot! This heat isn’t just a problem for intake temperatures, it is an issue for many other components within the engine bay. Many components have plastic or rubber elements that perish and crack when exposed to dramatic heat cycles, this can cause a variety of reliability issues over time. The positioning of the turbo may also lead to excessive heat to bodywork resulting in uncomfortable temperatures soaking through to the drivers footwell or paint damage to bodywork.

More critical is that the excessive heat of a turbo may result in uneven heating of the engine with one side exposed to significantly higher external temperatures than the other, this can lead to warping of the head and damaged gaskets. Insulating the turbo with a turbo blanket will hold the temperature within the turbine and stop the heat from soaking into other parts of the engine.

DEI GEN-3 Titanium Turbo Shield

The heat cycles that a turbo blanket go through are massive, this extreme heating and cooling asks a great amount from the materials in the shield and these can quickly begin to become brittle and break down. Knowing the extreme demands asked of the turbo blanket it makes sense to opt for a solution that is built to not only perform but also to last.

The innovative team at Design Engineering Inc have been producing industry leading turbo blankets for many years, using their knowledge of heat management and available materials to constantly push the boundaries on what is possible. This constant development has led to the Gen 3 Titanium Turbo Shield, the most technologically advanced shield on the market.

What DEI have to say about the Gen-3 Titanium Turbo Shield: “We incorporated all our experience to build the absolute best turbo shield on the market. By developing advanced textiles and diving deep into what is needed to control turbo heat, we developed the GEN-3 Titanium Turbo Shield. A silicone coated Titanium LR outer layer with multiple stainless steel and silica inner layers. Without a doubt the strongest, most heat resistant shield available”

DEI GEN-3 Titanium Turbo Shield, why is it the best turbo blanket on the market?

Outer shell: The outer shell of the GEN-3 turbo shield is built using LR technology, this takes pulverised lava rock and strands it into a fibre material before being woven into a proprietary weave. This titanium LR material is engineered for strength and chosen for performance and reliability.

For additional durability DEI have coated the complete outer layer in silicone, this prevents fraying of the titanium LR material and encases seams making them over 4 times stronger. This outer layer has been built to hold up even in the most extreme of conditions.

Insulation Layer: To ensure as much heat as possible is kept within the turbine of the turbo, DEI have included a thick layer of silica insulation within the GEN-3 turbo shield. Silica is known for having a very low thermal conductivity making this the perfect choice when insulating a turbo.

Inner Layer: The inner layer is built to hold the insulation layer within the shield and adds the required strength and form. A blend of stainless steel, glass fibre and silicone are used to add to the insulating and thermal properties of the shield. The choice of materials add insulation value along with increased seam strength and durability.

Inner cover: As a first barrier of protection, the GEN-3 Titanium Turbo Shield has a stainless steel fabric liner. This material has been chosen for its resistance to extreme temperature and will not break down or become brittle when exposed to the huge temperatures from the turbo.

As with all of DEI’s turbo shields, the GEN-3 is double stitched using stainless steel thread to hold up in the most extreme temperatures. True riveted anchors along with added seam protection for a shield that is stronger and easy to install.

Which size turbo blanket do I need?

DEI turbo shields are based on two measurements, the first measurement is the circumference of the turbo excluding the flange. The second measurement is the width of the turbo at its widest point excluding the flanges.

Once measured, please refer to the below chart to determine the correct shield for your turbo.

| TURBO | CIRCUMFERENCE | WIDTH |

| T22 | 15" | 2.25" |

| T25/28 | 15" - 16" | 2.5" |

| T3 | 15" - 16" | 2.5" |

| T4 | 20" - 22" | 2.75" |

| T6 | 26" | 3.75" |

| T6X | 26" | 4.25" |

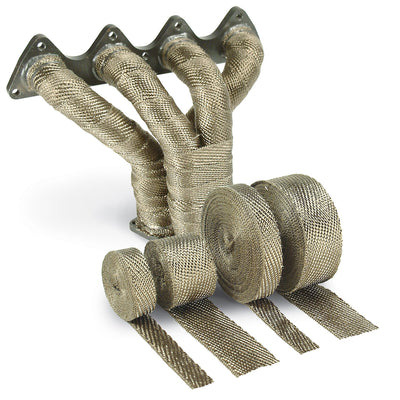

DEI Turbo Shields are available to purchase as a shield only or as a turbo blanket and wrap kit which also includes Titanium Exhaust Wrap and ties for you to insulate the down pipe taking exhaust gasses to the turbo. This is another step in reducing heat soak into the engine bay and ensuring the hot exhaust gasses remain hot as they enter the turbo, aiding efficiency of the turbo and helping to keep intake temperatures cool. For more information on exhaust wrap why not have a look at our exhaust wrap buyers guide.

When insulating your turbo it is also beneficial to insulate the wastegate, the reasons for this are much the same as insulating the turbo. Holding the heat within the wastegate ensures the hot gasses flow quickly and keep the turbo running at optimum conditions, also it prevents heat soak which is damaging to nearby components and bodywork. DEI have developed a wastegate heat shield which is designed to easily fit around the wastegate, this uses Titanium LR technology and the same high level of build quality you would expect from a genuine DEI turbo shield.

Thanks for reading this guide, for more information on other areas that can benefit from heat shielding please check out our introduction to heat management.