Exhaust wrap buyers guide

What does exhaust wrap do?

Exhaust wrapping has a number of benefits, let’s start with the headline one…

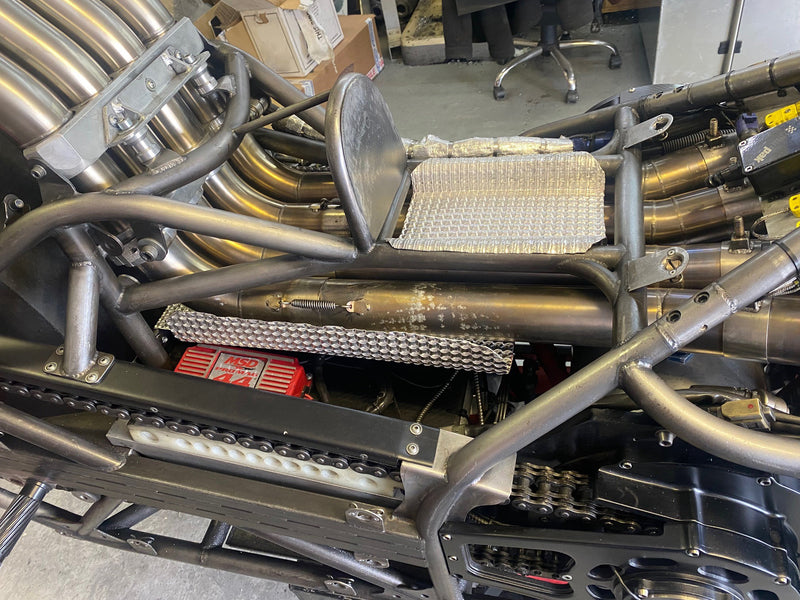

Exhaust wrapping adds power! - There are many variables involved so it is difficult to put a number on this but the science behind the power gains is really quite simple. The gasses in your exhaust are hot and therefore have a low density, as the heat escapes through the surface of the exhaust the density of the gasses inside increase and require more energy to escape the pipe, by insulating the exhaust with exhaust wrap you are keeping the gasses hot which keeps them moving quickly and allows the engine to perform more efficiently.Keeping the heat inside the pipe by installing a quality exhaust wrap will dramatically reduce under bonnet temperatures, this can be by as much as 70%. Keeping under bonnet temperatures down will reduce intake temperatures, this cooler air is more dense and will result in more power! For turbo applications it is also worth considering a turbo blanket to insulate the turbo and keep the under bonnet temperatures low.

Increased reliability - For other under bonnet components to function efficiently and reliably it is important to manage their exposure to radiant heat and the damaging effects caused by it. Often the first step in a good heat management program is to insulate the exhaust system with exhaust wrap, this reduced under bonnet temperature will vastly reduce the impact of heat on components, allowing them to function correctly.

Protect bodywork from heat damage - Also susceptible to damage from radiant heat is bodywork, engine bays are often very tight on space and the exhaust will run very close to painted areas of bodywork. This can lead to paint becoming damaged and flaking away, it can also lead to unwanted heat soaking through to other areas of the car which can make for an uncomfortable drive. Exhaust heat wrap is a great first step in keeping the heat where it is required and away from where it is unwanted.

Protect against burns - In motorsport applications it is common to need to work under the bonnet while the engine and exhaust are still hot, perhaps during a pitstop or shortly after a race. During this time there is a risk of burns to your skin as you reach over and work close to the exhaust, the exhaust wrap will act as a safety barrier to protect you in the event of accidentally touching the exhaust.

Motorcycle exhaust wrap - This safety and comfort benefit is also incredibly useful for motorcycles where exhausts frequently run close to the rider. Motorcycle exhaust wrap can also really boost the aesthetic of the bike, we supply exhaust wrap to a number of custom bike builders who frequently use exhaust wrap for that finishing touch!

Titanium exhaust wrap vs fiberglass?

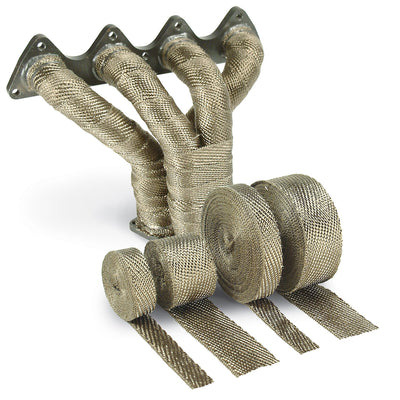

At Nimbus Motorsport we stock a large range of exhaust heat wrap options, all of which can be divided into two groups, glass fiber or lava rock.

Fiberglass exhaust wrap.

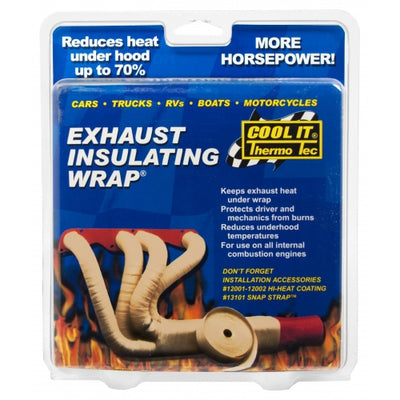

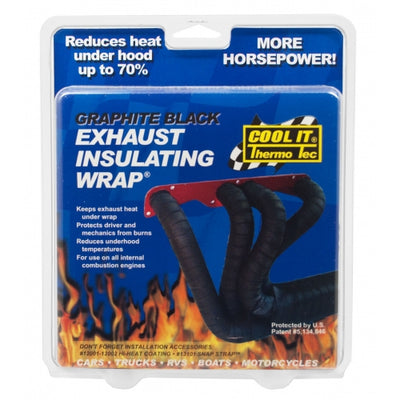

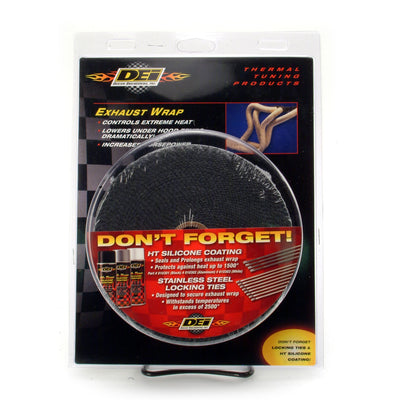

Fiberglass exhaust wrap has been around for many years, we began importing the Thermo-Tec range of exhaust wrap 30 years ago and the core range of products remain unchanged even now, we added DEI shortly after and have stocked both of these premium ranges ever since. These premium glass fiber exhaust wraps have specialist coatings which are designed to prevent against the damage which can be caused by over-insulating, a problem associated with poor quality un-coated wraps. These specialist coatings conduct heat across the surface of the wrap which help to evenly control heat and dissipation. Once installed, glass fiber exhaust wrap can be coated with a hi-temp silicone coating, this seals the wrap and protects it against leaks and spills under the bonnet.

Titanium exhaust wrap.

The alternative to fiberglass based exhaust wrap are wraps that are produced using lava rock. DEI have a range of lava rock based wraps which are called Titanium Exhaust Wrap, Thermo-Tec also offer an equivalent lava rock based wrap which they name Thermo-Tec Rogue Performance Products.

The lava rock based material is produced by utilizing pulverised lava rock called basalt, this is stranded into fiber material and then woven into the final exhaust wrap product. Lava rock based wraps are extremely pliable and do not require any pre-wetting before use, this allows a tighter and more secure installation. Lava rock exhaust wraps also have high resistance to oil spills and vibration which make the product extremely durable for the long term, the temperature range is also higher with Design Engineering Inc Titanium Exhaust Wrap capable of withstanding 1800°f direct heat and 2500°f intermittent heat.

The resistance to spills also makes it unnecessary to coat lava rock based exhaust wrap with a hi-temperature silicone coating, you are still able to use a coating but it would only serve aesthetic purposes.

Exhaust wrap pros and cons.

Wrapping an exhaust has many positive effects but there are some applications where it would be advised not to use the product. If your exhaust manifold is already ceramic coated then it would not be advised to use an exhaust wrap over this, it will not damage the steel but the ceramic coating will likely begin to crack and flake away. We would also advise not to use exhaust wrap on a titanium exhaust system, these are very thin pipes designed to dissipate heat quickly, insulating these with exhaust wrap will keep the heat in the pipe for too long and could lead to cracking. Similar to this would be poor quality exhaust systems, these tend to be made from thin steel which may degrade quickly if over insulated. If exhaust wrap is not suitable for your application but you have an exhaust running close and causing damage to other components or bodywork then there are other heat management solutions available to combat this, please do not hesitate to contact us and we’ll be very happy to discuss options with you.

Exhaust wrap myths

With 30 years of experience supplying heat management products into the motorsport, automotive and commercial industries we have heard all the common worries about using exhaust wrap. The truth is that most of the worries are valid but all are based on substandard product, exhaust or installation.

Will exhaust wrap rust exhaust pipe?

All steel exhausts will eventually rust with or without exhaust wrap. Poor quality exhausts tend to be made of extremely thin steel, keeping the heat within these pipes by using exhaust wrap may cause the steel to degrade at a quicker rate which could accelerate the aging of the steel increasing the possibility of rust sooner. A quality exhaust system will be made of steel which can handle the temperature cycles associated with exhaust wrap, for this application the wrap will not have a negative effect on the steel.

Exhaust wrap is designed to keep the heat in the exhaust, it is essential that the wrap evenly conducts heat across the surface to avoid hotspots that may negatively impact the exhaust. We only stock premium brands of exhaust wrap, these have coatings within the wrap to conduct heat and ensure it is evenly distributed. Poor quality wraps are un-coated and susceptible to the heat becoming excessive in one spot, this can be damaging for exhaust systems.

A correct installation is also key, this maximises the effectiveness of the exhaust wrap and mitigates any negative side effects. A ¼” overlap is recommended to get the most out of the product, over wrapping the exhaust with multiple layers of wrap will not improve the performance of the product but may have negative side effects due to over insulation.

Thanks for reading this guide, for more information on other areas that can benefit from heat shielding please check out our introduction to heat management.