Introduction to engine bay heat management

A good heat management program can make a huge difference to the performance and reliability of any performance vehicle. With so many products on the market it can be difficult to know where to start, that is why we have put together this guide so that you can decide which options are best for your application and quickly begin seeing the performance benefits available.

There are a range of key areas to address with heat management, we have broken these down and picked out our recommended products for each area and the benefits that they offer.

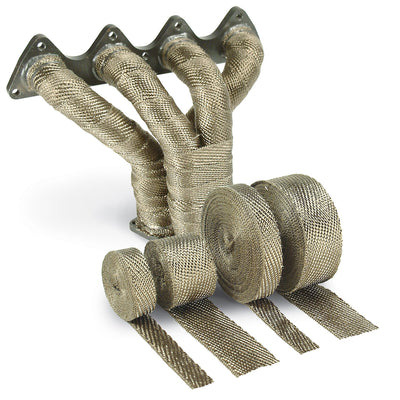

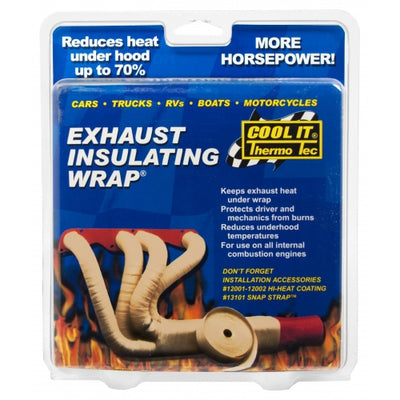

Exhaust Wrap

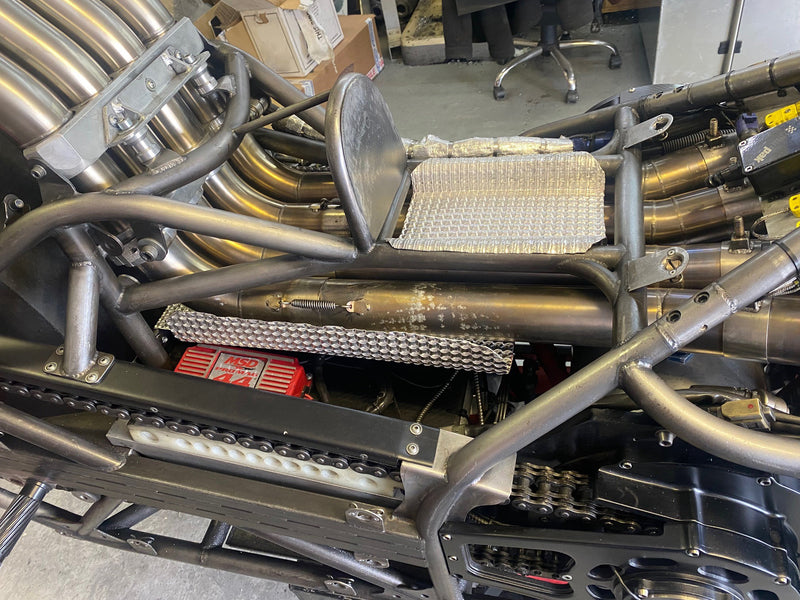

An excellent place to start with heat management is with a good quality exhaust wrap. One of the main aims of heat management is to keep under bonnet ambient temperatures as low as possible so that the engine has a reliable source of cool air for intakes, hot exhaust manifolds are therefore one of the first problem areas we can look at to manage these under bonnet temperatures. By insulating the exhaust manifold with exhaust wrap you are keeping the heat of the exhaust gasses within the exhaust system and stopping this heat from soaking out into the engine bay. This insulated exhaust keeps the under bonnet temperatures down but the benefits do not stop there. The hotter the exhaust gasses are kept, the more energy they have and the quicker they can escape the pipe, this aids the efficiency of your engine and performance increases.

Often exhaust manifolds are squeezed into small spaces running close to other components and bodywork which are susceptible to heat damage. By wrapping the exhaust you are shielding these components allowing them to perform reliably while also protecting paint from blistering. Our go-to recommendations are the Thermo-Tec Original Exhaust Wrap and the DEI Titanium Exhaust Wrap, for more detail on the benefits of these and how to choose the best exhaust wrap for your application head over to our exhaust wrap buyers guide.

Turbo Blanket

For turbocharged engines you not only have a hot exhaust manifold to consider with your heat management plan, you also have a turbo which is often the hottest thing under the bonnet. Much of the principles are the same as fitting exhaust wrap, your aim is to hold the heat within the turbine of the turbo and prevent it from radiating out into the engine bay. Holding the heat within the turbine of the turbo will keep gasses hot and moving quickly, this results in faster spool-up times and delivers a more linear power curve. Keeping the turbo insulated with a turbo blanket will lower under bonnet temperatures and mean that the turbo has access to cooler, more dense, air packed full of oxygen for your intakes.

Turbo blankets are given an incredible amount of abuse, they go through extreme heat cycles and over time the materials harden and become brittle, at this point the blanket can become loose and tear. DEI have built the GEN-3 Titanium Turbo Shield to be the strongest turbo blanket on the market, a built-in stainless steel liner is a robust first layer of defence against the extreme temperatures from the turbo. A silica layer is used for its low thermal conductivity properties which is the perfect choice for insulating the turbo and keeping the heat contained, this is built into an inner layer strengthened by stainless steel, glass fibre and silicone. The outer layer uses DEI’s Titanium LR technology and is again chosen for performance and durability, this is coated in silicone to encase all joins and stitching and act as another layer of strength, making this the most technologically advanced turbo blanket on the market. Learn more about the benefits of using a turbo blanket.

Line and hose sleeving

There are a variety of critical wires and hoses in your engine bay, delivering power and fluids where they are required for the engine to run properly. These wires and hoses can run very close to heat sources such as exhaust manifolds which exposes them to temperatures that are not optimal. The exposure to extreme heat results in cracking of hose and wires as the plastics and rubbers perish, this introduces reliability issues long term.

Fuel lines are very susceptible to temperature, much like air for your intake, the fuel arriving at your engine benefits from being as cool as possible. Cooler fuel is more dense which allows more to enter the combustion chamber, as the fuel gets hotter it expands meaning that the same amount of fuel takes up more space and is less efficient. The worst case scenario is that the fuel gets so hot that it vaporises, this means that there is no fuel reaching the combustion chamber, this creates an issue known as vapor lock.

Insulating critical wires and hoses is an effective way to keep them running within their optimum temperature range, protecting against poor connections due to perished plastics and also against under bonnet spills. For hoses running in very close proximity to a heat source we recommend the DEI Fire Sleeve, this material withstands 500°f direct heat which means that it can be touching this heat source without any problem. For areas with high levels of radiant heat we recommend the Thermo-Tec Thermo-Sleeve, this aluminised heat sleeve is excellent at reflecting radiant heat and is safe to use up to 2000°f.

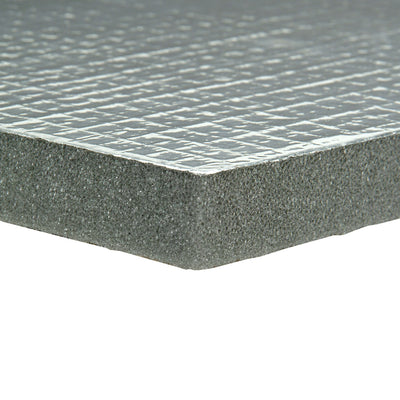

Firewall heat barrier

Heat from the engine bay will always look to transfer through nearby metal surfaces, the firewall has a large surface area and commonly has heat sources running close to it which makes this an area vulnerable to heat soak within the engine bay. Heat transferring through the firewall can make for an uncomfortable ride as it soaks through and enters the driver cabin, raising the temperature within the car and risking burns to your feet. Exhaust manifolds and turbos positioned close to the firewall can create hot spots that crack and blister painted bodywork within the engine bay and also on the opposite side within the drivers cabin.

The best way to combat this is by applying a heat barrier to the surface of the firewall, this can cover the full surface or can be applied locally in smaller patches to specific problem areas. We would recommend the Thermo-Tec Aluminised Heat Barrier to be used in this application, this material will reflect heat away from the firewall to protect bodywork and help keep cabin temperatures low.

Transmission Tunnel heat shield

Transmission tunnels are positioned close to your firewall and can suffer from very similar heat issues. Transmission tunnels run underneath the car and pass between the driver and passenger seats, this raised tunnel houses the all important transmission and transfers power to the rear wheels depending on your drivetrain. This tunnel is also a convenient space to run exhausts as it gets the pipes up and out of the way rather than hanging low below the floor of the car. All of this generates heat which can transfer up through the tunnel and into the car, exposing painted surfaces to heat damage at the same time.

To manage heat in this area it is good practice to install a transmission tunnel heat shield. We recommend the DEI Floor and Tunnel Shield, this product is designed for this specific application and is perfect for the conditions experienced in this area of the car. This area is exposed to extreme heat cycles but also gets a hard time from road debris, wind and rain. DEI Floor and Tunnel shield is a durable solution built to withstand these elements while performing as a highly effective heat barrier. The material has an aluminium top which is easily formable by hand, this is backed with a layer of temperature resistant glass fibre. Installation is simple thanks to the self-adhesive backing, simply shape, trim, peel and stick!

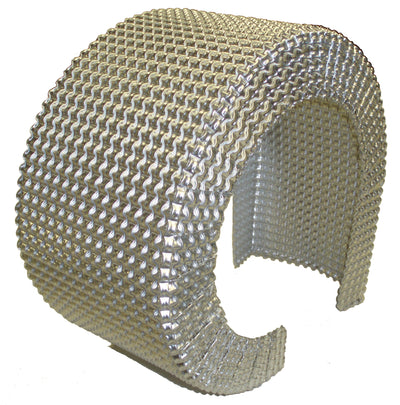

Exhaust Heat Shield

Underneath the majority of road going cars you will not have to search too hard to find a fabricated heat shield positioned above the exhaust. These shields are positioned to deflect heat away from nearby components to extend their life, and also deflect heat away from bodywork to protect paint and stop heat from soaking through into the cabin.

These shields are simple but extremely effective, most modern cars will build these shields out of a dual layer aluminium such as the Nimbus G2. The same principles can be followed when putting together a race car or any custom car build, a simple aluminium exhaust heat shield can be extremely effective. Learn more about the benefits of the Nimbus G2 heat shield.

Cold Air Intake - Gold Heat Tape

As mentioned in a few other areas in this article, air is a gas which means it changes its density depending on temperature. The cooler the air, the more dense it is. Cool air intakes are fitted to performance cars to pull in cold air from outside the engine bay, this air is then taken along a wider intake tube allowing it to get to the combustion chamber with the least amount of resistance. This setup delivers a reliable supply of cool air but the intake pipe itself can become a heat sink if exposed to high temperatures under the bonnet. Fitting a reflective barrier such as gold reflective tape will reflect ambient heat away from the intake to promote a cooler, denser, more powerful air charge. We recommend using DEI Reflect-a-Gold, this tape can be used as a cold air intake wrap and is easily installed with the self-adhesive backing. This material is a highly effective heat shield capable of withstanding continuous temperatures of 800°f despite being extremely lightweight and having a low profile of just 0.0065” in thickness.

Under Bonnet Heat Barrier

With all of the focus on heat management solutions in and around the engine bay we shouldn’t forget about the bonnet itself. With a few of the above heat management solutions installed you should already be well on the way to your goal of cooler under bonnet temperatures but to protect the bonnet from heat and add ensure longevity of your paint job it is worth looking at under bonnet heat barriers. Our recommendation is the DEI Under Hood Thermal Acoustic Lining which is designed to insulate the underside of your bonnet, serving as a sound deadener and protecting paint from blistering. Made from ¾” thick industrial acoustical grade foam with a reinforced reflective aluminium surface.

There are many heat issues under the bonnet that can be solved with an effective heat management program, encouraging long term reliability of components and an increase in performance. Nimbus Motorsport have imported Thermo-Tec and DEI products since we began business 30 years ago, adding the Nimbus Heatshield to our range we have products that we know and trust for all heat management applications from motorsport through to commercial industries. We hold stock of the full product ranges in our UK warehouse and have a technical team who are happy to discuss any heat management solutions over the phone to make sure you get the right product for the job.